15/11/2022

What are the characteristics of rebound foam?

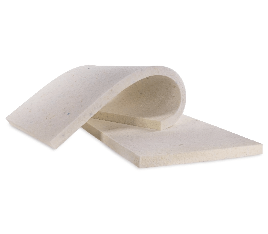

Rebound polyurethane foam, referred to as “type R”, is a versatile product. It can be found e.g. in the construction of furniture, sports equipment and car equipment. What is it and why has it become so popular?

What does “rebound” mean?

Type R foam is produced from scraps of flexible foam – so it can be said that it is an environmentally friendly material. The foam cuttings are ground into fine fragments, a polyurethane binder is added and it is subjected to re-foaming. Through repeated foaming, the material gains a number of properties desired in industry.

Benefits of rebound foam

Rebound foam is characterised by high density, hardness and flexibility. An important feature is its resistance to pressure. It very effectively reduces vibrations and oscillations, and is also resistant to moisture and temperature fluctuations. Type R foam conducts heat well and is characterised by high vapour permeability. The product does not contain substances harmful to health (e.g. heavy metals), so it is also perfect, for example, in the production of rehabilitation equipment that comes into contact with the skin. Rebound foam is also highly resistant to chemical substances.

Type R foam is produced in different densities, so you can easily adjust its type to a specific task. The one with a lower density is used e.g. for the production of backrests, armrests, headrests, and the high-density one, as a stiffener. The foam provides great protection for goods in transport, acoustic and anti-vibration insulation for working machines and thermal insulation for some products. There are many uses for the foam, depending on the density you choose. More information on our website.